Pneumatic control valves are essential components in various industrial processes, enabling precise regulation of fluid flow, pressure, and temperature. Understanding their working principles is crucial for optimizing system performance and ensuring operational efficiency.

Fundamentals of Pneumatic Control Valves:

A pneumatic control valve modulates the flow of fluids or gases by adjusting the size of the flow passage, responding to signals from a controller. This direct manipulation allows for the control of process variables such as pressure, temperature, and liquid levels.

Key Components and Operation:

- Valve Actuator: This component moves the valve’s modulating element (e.g., ball or butterfly) based on the control signal. Pneumatic actuators are favored for their simplicity, requiring only a compressed air supply.

- Valve Positioner: Ensures the valve reaches the desired degree of opening, overcoming issues like friction and wear. Positioners can be pneumatic, analog, or digital, with digital versions offering advanced diagnostics and two-way communication.

- Valve Body: Contains the modulating element (such as a plug, globe, ball, or butterfly) that directly influences the fluid flow.

Control Actions and Fail-Safe Modes:

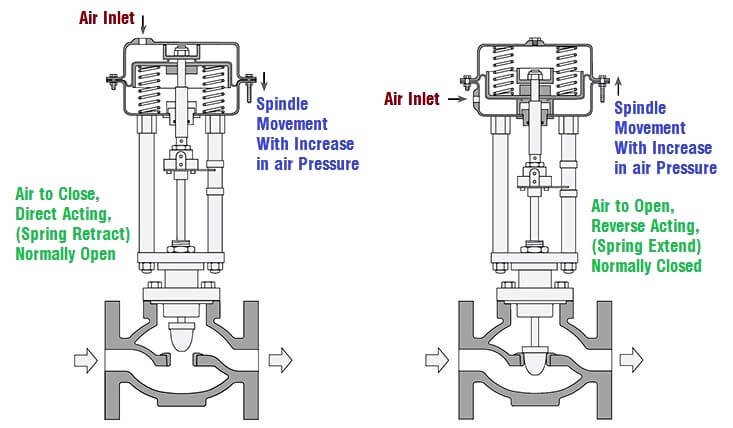

Pneumatic control valves can be configured for different control actions:

- Air-to-Open: The valve opens as the control signal increases.

- Air-to-Close: The valve closes as the control signal increases.

Additionally, valves are designed with fail-safe modes to ensure safety during control signal or air supply failures:

- Fail-Closed: The valve closes upon signal or air supply loss.

- Fail-Open: The valve opens upon signal or air supply loss.

The appropriate fail-safe mode is selected based on the specific safety requirements of the process.

Advancements in Pneumatic Control Valve Technology:

Recent developments have enhanced the functionality and efficiency of pneumatic control valves:

- Digital Valve Controllers: Modern positioners equipped with microprocessors enable real-time diagnostics and two-way communication, simplifying setup and maintenance.

- Energy Efficiency: Innovations in valve design aim to reduce compressed air consumption, lowering operational costs and environmental impact.

- Enhanced Materials: The use of advanced materials improves durability and compatibility with a wider range of fluids, extending valve lifespan and reliability.

Conclusion

Pneumatic control valves are vital for maintaining precise control over industrial processes. A thorough understanding of their operation, components, and recent technological advancements is essential for selecting and maintaining valves that meet specific application requirements. Staying informed about these developments ensures optimal performance, safety, and efficiency in industrial systems.

Why Choose HybridOX Automation LLP?

At HybridOX Automation LLP, we are a leading manufacturer, supplier, and exporter of premium-quality industrial control valves. Our extensive range of pneumatic control valves, actuators, and automation solutions ensures enhanced efficiency, safety, and cost savings for industries worldwide. With a focus on cutting-edge technology and industry-specific solutions, we provide customized flow control products that meet the evolving demands of oil & gas, chemical, food & beverage, and water treatment sectors. Contact us today to explore how our high-performance control valves can optimize your industrial automation needs.