- Home

- Products

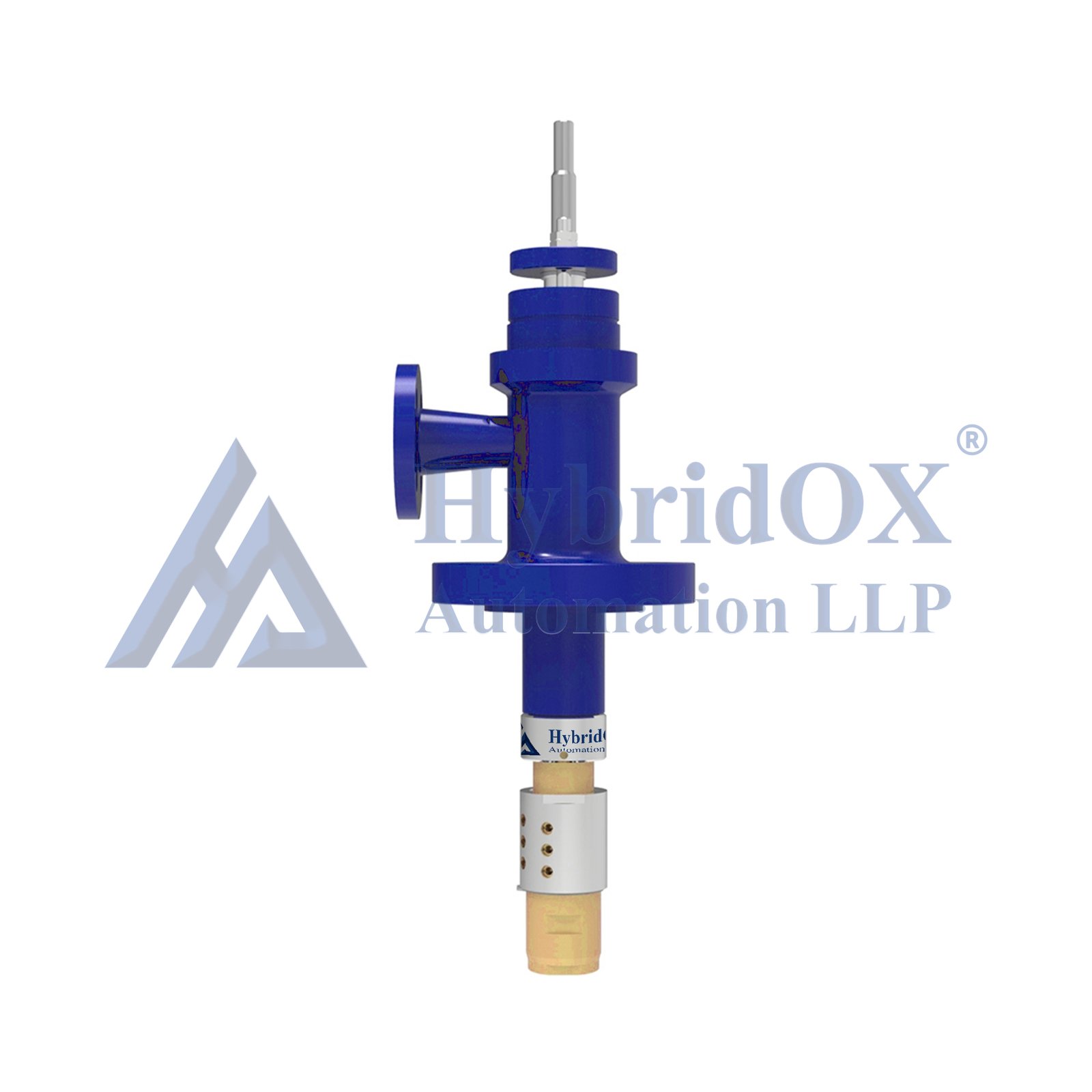

- Desuperheater

pneumatic

Desuperheater

The Desuperheater from HybridOX Automation LLP. is a cutting-edge heat exchanger that efficiently reduces the temperature of superheated steam utilized in industrial processes. By adding precisely calculated volumes of cooling water to the steam, the Desuperheater effectively lowers the temperature of the superheated steam to the necessary level, improving process efficiency and protecting downstream equipment.

This gadget ensures precise temperature management and increases operating safety in a variety of high-temperature applications.

Technical Specifications

| STEAM LINE SIZE | 25 mm to 400 mm NB |

| CONNECTION SIZE | Steam Side Mounting Flange – 80 NB |

| WATER SIDE FLANGE | 25 mm, 40 mm NB |

| PRESSURE RATING | 150# to 2500# |

| BODY MOC | Carbon Steel / Alloy Steel / Stainless Steel |

| NOZZLE MOC | SS 316 (Stellited optional) |

| ACTUATOR | Pneumatic / Electrical |

| RANGEABILITY | 40:1 |

| END CONNECTIONS | Flanged |

Performance and Design Features

| Fixed Nozzle Type |

|

| Venturi Nozzle Type |

|

| Variable Type |

|

Unique Selling Points (USP)

The powerful structure, advanced mixing technique, efficient temp reduction of the HybridOX Automation LLP, Desuperheater set it apart. Its high performance, small size, and adjustable flow control make it a reliable choice for precise steam temperature control in a range of industrial applications. The device’s integrated safety features and ease of maintenance further increase its value and operational dependability.

This outstanding Desuperheater, which combines state-of-the-art engineering and exquisite craftsmanship to satisfy a wide range of worldwide industry demands, is proudly produced and distributed by HybridOX Automation LLP. By using a spray nozzle to inject atomized water into the superheated steam flow, mechanical atomizing type desuperheaters typically reduce the temperature of the steam to the desired set point.

Product Application

- Chemical Processing

- Oil and Gas Industry

- Water and Wastewater Treatment

- Power Generation

- HVAC Systems

FAQs

A desuperheater is a device that mixes superheated gases or steam with a predetermined volume of water or another cooling medium to lower their temperature. It efficiently brings the steam or gas’s temperature down to a predetermined point before it moves on to the next phase of processing.

The superheated steam or gas stream is injected with a predetermined volume of water to function as a desuperheater. Heat is transferred and the steam cools to the proper temperature when water and steam are combined. The desuperheater uses a variety of techniques, including indirect heat exchange and direct injection, to precisely regulate the temperature.

Typically, desuperheaters are made of materials like:

Stainless steel: Due to its resistance to corrosion and capacity to tolerate high temperatures.

Alloy steels: For applications requiring strength and durability under high temperatures and pressures.

Carbon Steel: For less demanding circumstances and more affordable alternatives.

Specialty alloys: Suitable for corrosive conditions and extremely high temperatures.

Take into account the following elements:

Temperature Range: Verify that the desuperheater is capable of handling the steam or gas temperature in your application.

Flow Rate: Align the steam or gas flow rate with the desuperheater’s capacity.

Material Compatibility: Select materials that are appropriate for the operating conditions and the steam or gas.

Control Method: Select a desuperheater with the appropriate control mechanisms for your needs.

Typical upkeep consists of:

Inspection: Continually look for corrosion, leaks, or wear.

Cleaning: Get rid of any buildup or obstructions that can impair functionality.

Make that temperature sensors and controls are calibrated correctly.

Checking Components: Examine and replace any worn or damaged parts as necessary.

Absolutely, but make sure the desuperheater is built to withstand high pressure. Make that the desuperheater’s construction and materials are appropriate for the pressure conditions in your application.

In contrast to alternative cooling methods, a desuperheater provides:

Accurate temperature control of steam or gas is made possible by precise temperature control.

Effective Cooling: Uses heat exchange or controlled water injection to provide effective cooling.

Adaptability: Fit for a variety of uses and temperatures.

Desuperheaters of the highest caliber are produced and exported by HybridOx Automation LLP., Contact us right now for dependable and effective temperature control systems that are customized to meet your demands.