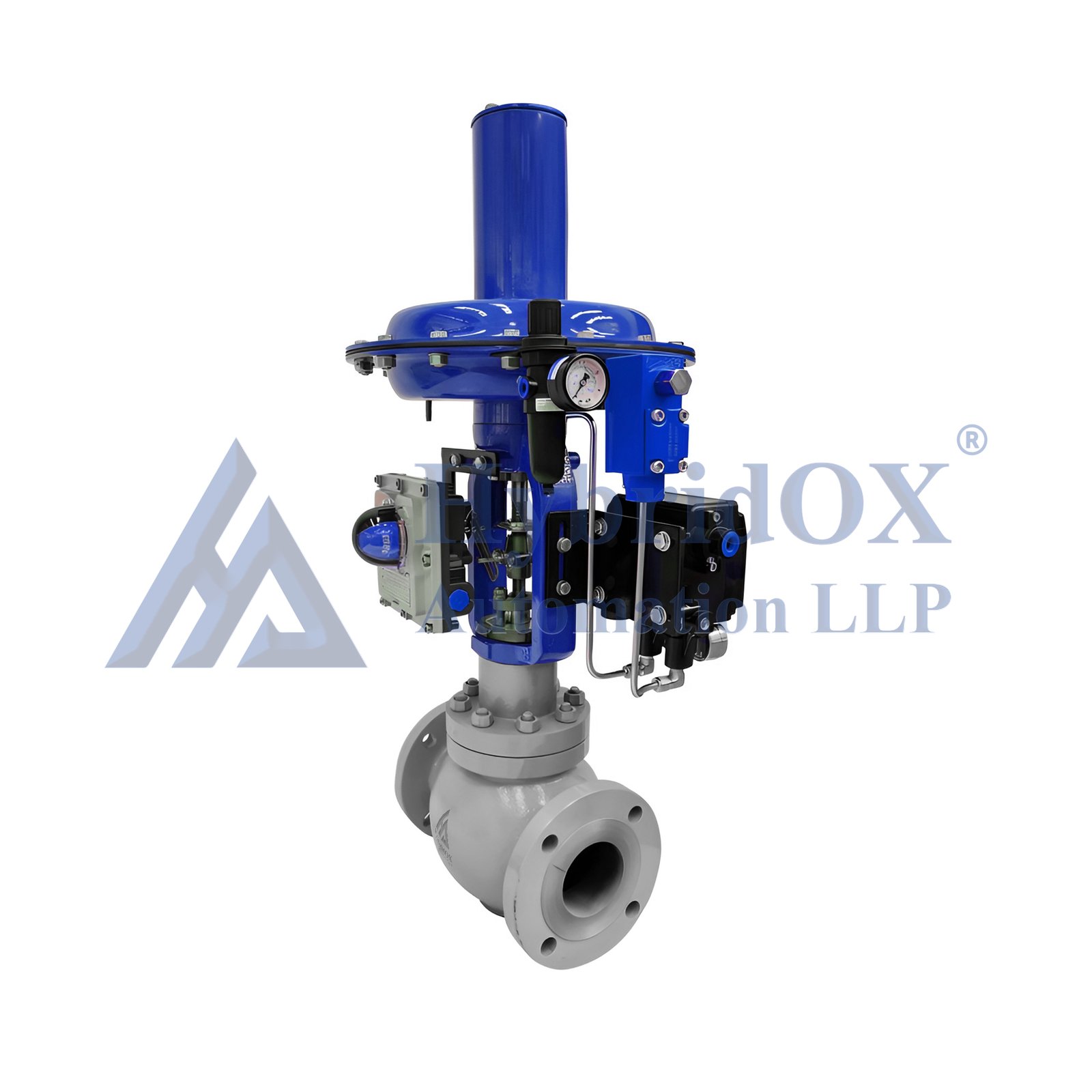

pneumatic

Two-Way Control Globe Valve

The Two-Way Control Globe Valve manufactured by HybridOX Automation LLP. is built to provide precise and reliable fluid control for various industries. With this valve, flow regulation can be achieved due to its linear motion system and globe shaped body.

The Two-Way Control Globe Valve developed by HybridOX Automation LLP. (Previously HybridOX Automation UK LTD.) is constructed to withstand a wide variety of operating conditions whilst maintaining high performance, safety, and reliability in severe working environments.

Technical Specifications

| DESIGN | ASME B16.34 |

| VALVE SIZE | 15 to 450 mm (½” to 18″) |

| RATING | 150 to 2500 ANSI |

| END CONNECTION | Flanged, Screwed, Buttweld, Socket Weld |

| MATERIAL | Carbon steel, Stainless steel, Monel, Duplex, Alloy 20, Hastelloy B/C, Aluminium Bronze, PFA Lined, etc. |

| BONNET | Standard from -20°C to 250°C, Normalizing between 250°C to 500°C, Extended Bellow Sealed |

| TRIM FORMS | Top guided, Contoured, Splined, Micro flow, V-Ported (Balanced / Unbalanced), Low Noise (Up to four Stage Pressure Reduction, Balanced / Unbalanced) |

| FLOW CHARACTERISTICS | Equal Percentage, Linear, and Quick Opening |

| SEAT LEAKAGE | Class III, IV, V, & VI (FCI-70.2) Standard Leakage Rates Metal to Metal Seating: Class IV (less than 0.01% of rated CV) Metal to Soft Seating: Class VI (Bubble tight, < zero leakage) |

| GLAND PACKING | Grafoil or PTFE Chevron |

| ACTUATOR | Diaphragm, Piston, or Electrical, Direct / Reverse Acting |

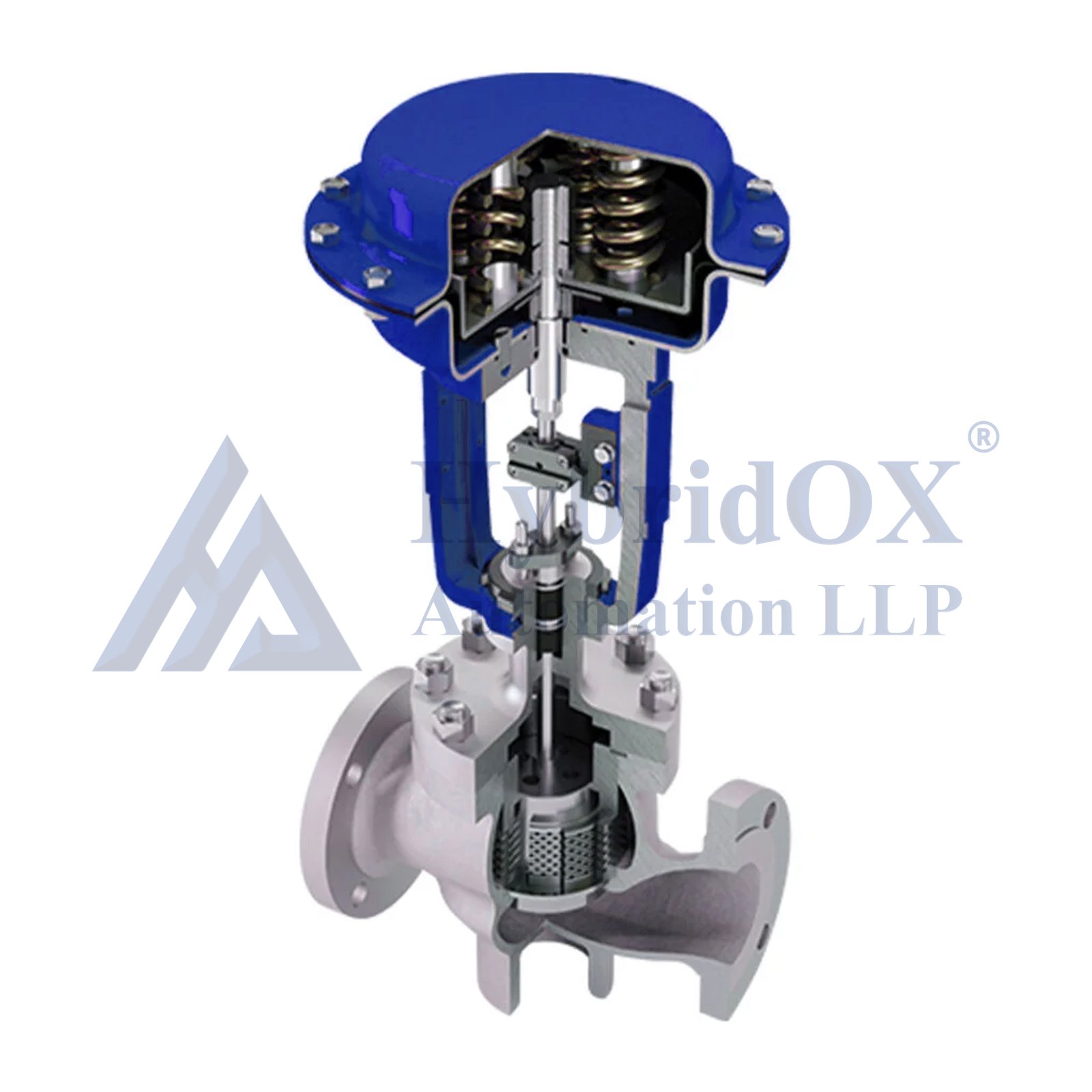

Construction and Build

| Component | Details |

|---|---|

| BODY | Durable materials (stainless steel, carbon steel), globe-shaped for efficient flow control. |

| TRIM ASSEMBLY |

Valve Seat: Precision-machined for tight sealing. Plug: Adjustable for smooth flow control. Stem: Connects plug to actuator for precise adjustments. |

| ACTUATOR | Pneumatic diaphragm or piston type, made from robust materials for reliable operation. |

| POSITIONER | Ensures accurate valve position based on control signals. |

| MANUAL OVERRIDE | Allows manual adjustment if pneumatic power fails. |

| SEALS AND GASKETS | High-quality elastomers or PTFE for leak-proof performance. |

| MOUNTING FLANGES | Standard sizes for easy integration. |

Product Features

Precision Flow Control: HybridOX Automation LLP’s Two-Way Control Globe Valve’s precision flow control design enables adjustment of pressure drops and flow rates. It is perfect for applications needing precise flow management because of its linear motion mechanism, which allows for precise adjustments.

Robust Construction: HybridOX Automation LLP’s globe valve is made to handle high pressures, corrosive conditions, and extreme temperatures. It is made of premium materials like carbon steel, stainless steel, or advanced alloys. This sturdy design ensures long-term dependability and durability.

Flow Direction Control: HybridOX Automation LLP’s Two-Way Control Globe Valve, which is made to control flow in both directions, provides flexibility in system design and operation by successfully managing both forward and reverse flow channels.

Enhanced Sealing Performance: HybridOX Automation LLP’s globe valve offers superior sealing performance, preventing leaks and upholding a tight seal under high pressure circumstances thanks to its precision-machined seats and premium sealing materials. This improves operational effectiveness as well as safety.

User-Friendly Design: The valve’s optional position indications and simple controls make it simple to monitor and operate. It also has the ability to manually override, so manual modifications can be made as needed.

Versatile Actuation Options: There are several ways to operate HybridOX Automation LLP’s Two-Way Control Globe Valve, such as via a handwheel, electric actuator, hydraulic actuator, or pneumatic actuator. Compatibility with a wide range of automation installations and control systems is ensured by this versatility.

Temperature and Pressure Resilience: HybridOX Automation LLP’s Two-Way Control Globe valve is designed to function in harsh conditions over a broad range of temperatures and pressures. This allows it to accommodate high-temperature and high-pressure applications while maintaining reliable performance.

Unique Selling Points (USP)

Our Pneumatic Two-Way Control Globe Valve is distinguished by its remarkable precision, robust construction, and adaptable actuation options. Its globe-shaped design ensures accurate flow control and reliable performance across a broad temperature and pressure range. The HybridOX Automation LLP’s Globe Valve is a great choice for critical applications since it has user-friendly features and better sealing performance.

Its importance in fluid control system optimization and the achievement of operational perfection is highlighted by its resistance to corrosive and high-pressure environments, as well as its versatility in terms of control and integration possibilities. This superior Two-Way Control Globe Valve is proudly manufactured and exported by HybridOx Automation LLP’s, which combines outstanding workmanship and cutting-edge engineering to satisfy the various demands of industries across the globe.

Product Application

- Chemical Processing

- Oil and Gas Industry

- Water and Wastewater Treatment

- Power Generation

- HVAC Systems

FAQs

One kind of valve used to control pipeline flow is the two-way globe control valve. It controls the flow of gas or fluid through an adjustable disc and seat using a globe-shaped body. Precise control over pressure and flow rates is possible with this system.

A plug or disc is moved against a stationary seat within the valve body to operate the valve. The actuator allows either human or automatic control of this movement, which modifies the fluid’s flow rate or pressure as it passes through the valve.

Typically, two-way globe control valves are made of the following materials:

• Stainless steel: For durability and resistance to corrosion.

• Brass: Due of its corrosion resistance and malleability.

• Cast iron: For durability and economy.

• Plastic: For applications requiring chemical resistance and light weight.

Take into account the following elements:

• Flow Rate: Verify that the valve has the necessary flow capacity.

• Pressure Rating: Make sure the valve’s pressure rating meets the needs of your system.

• Material Compatibility: Select materials that are in harmony with the controlled fluids.

• Actuation Type: Depending on your control requirements, choose between automatic and manual actuation.

Typical upkeep consists of:

• Examine the item for wear, leaks, and correct functioning.

• Cleaning: Get rid of any buildup or debris that could impair performance.

• Lubrication: When necessary, lubricate moving parts.

• Make that the valve is calibrated to work within the given specifications.

Yes, but you have to be sure the valve you choose is made of materials that are resistant to high temperatures. Make that the valve’s specs align with the application’s temperature requirements.

Two-way globe control valves, as opposed to other types, have the following advantages:

• Increased Precision: Accurate management of pressure and flow.

• Improved Performance: Fit for uses where minute adjustments are necessary.

• Complexity: Offers better control but is typically more sophisticated than ball or gate valves.

One of the top producers and exporters of two-way globe control valves is HybridOX Automation LLP, Get in touch with us for premium control valves and solutions for valve automation that are customized to meet your demands.