Introduction

In modern industrial automation, pneumatic control valves play a crucial role in regulating fluid and gas flow. However, to achieve precise control, efficiency, and reliability, valve positioners are often used. A valve positioner ensures that a control valve accurately reaches the desired position based on input signals. This article explores the role of valve positioners in pneumatic systems, their benefits, types, and the latest trends in industrial applications.

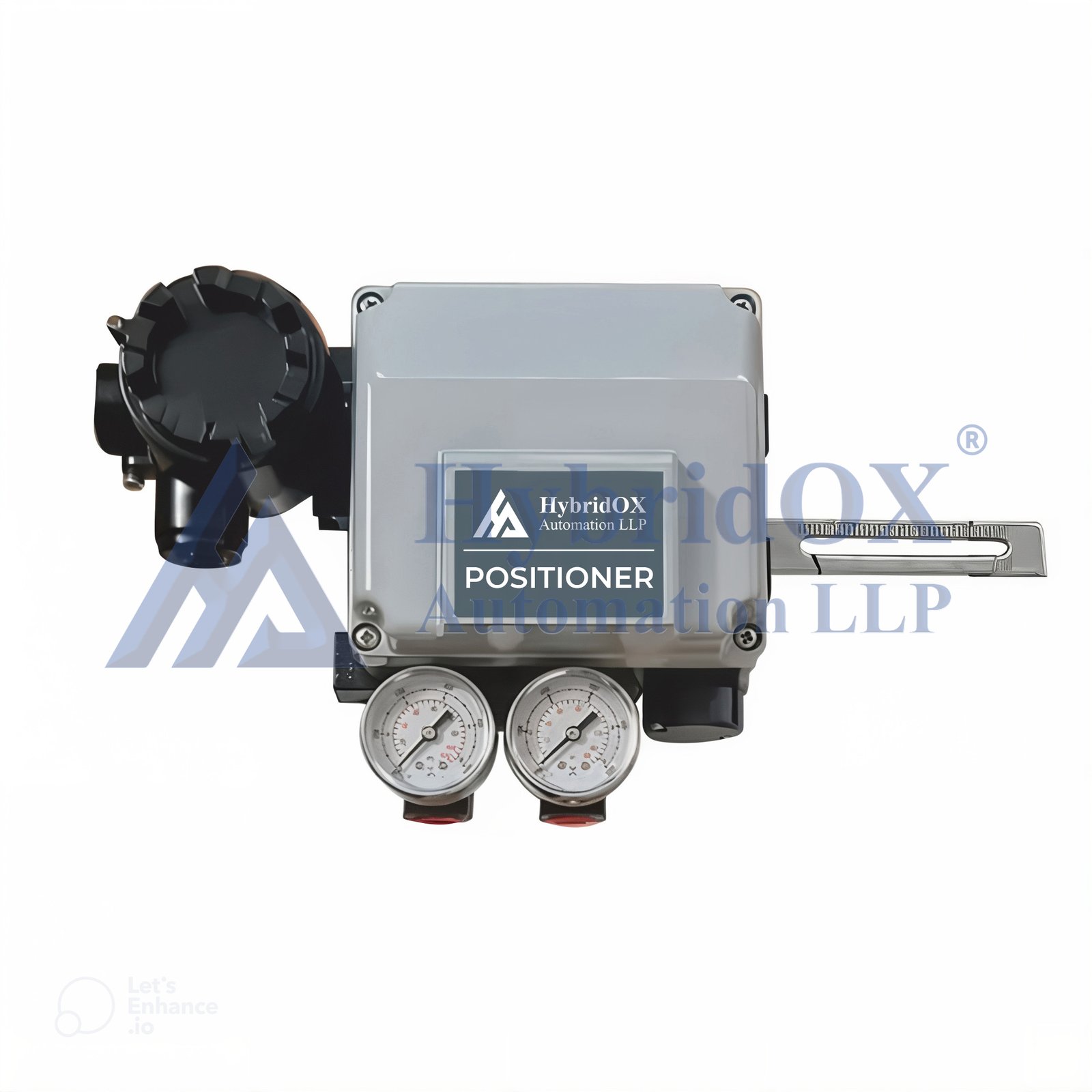

What is a Valve Positioner?

A valve positioner is a device that adjusts a control valve’s position to match the setpoint dictated by a process controller. It ensures that the valve actuator moves precisely to the required position, compensating for friction, pressure fluctuations, and wear over time. Without a positioner, valves may suffer from inaccuracies, leading to inefficiencies in process control.

Why Are Valve Positioners Essential in Pneumatic Systems?

- Improved Accuracy and Control

- Positioners ensure the valve reaches the exact position needed for optimal flow regulation.

- Eliminates hysteresis and deadband issues that can affect traditional actuator movements.

- Faster Response Time

- In dynamic processes, quick adjustments are necessary to maintain operational stability.

- Positioners enhance the response time of pneumatic actuators, improving system efficiency.

- Compensation for Actuator Non-Linearity

- Pneumatic actuators may experience friction or load changes.

- Positioners continuously adjust valve movement to ensure smooth operation.

- Energy Efficiency

- By optimizing valve movement, positioners reduce excessive compressed air consumption.

- This results in lower operating costs and improved sustainability.

- Extends Valve Life

- Positioners minimize wear and tear by preventing unnecessary valve movements.

- Reduces maintenance needs and extends the overall lifespan of the valve.

Types of Valve Positioners:

- Pneumatic Valve Positioners

- Operate using air signals to control valve position.

- Ideal for environments where electrical components are unsuitable due to explosion risks.

- Electropneumatic Valve Positioners

- Convert an electrical control signal (4-20mA) into a pneumatic output.

- Common in industries that require automated and precise control.

- Digital or Smart Positioners

- Utilize microprocessors and sensors to enhance control accuracy.

- Offer features like self-diagnostics, predictive maintenance, and remote monitoring.

- Hydraulic Valve Positioners

- Used in high-pressure applications where pneumatic signals may not be sufficient.

- Provide powerful and stable valve control in demanding environments.

Latest Trends in Valve Positioners

- Integration of IoT and Industry 4.0

- Smart positioners now come with real-time monitoring, predictive analytics, and remote control capabilities.

- Wireless communication allows plant operators to manage valve performance remotely.

- AI-Based Predictive Maintenance

- AI algorithms analyze valve performance data to predict potential failures.

- Helps industries reduce unplanned downtime and optimize maintenance schedules.

- Energy-Efficient Pneumatic Systems

- Manufacturers are focusing on low-power, high-efficiency valve positioners.

- Reducing air consumption helps industries meet sustainability goals and lower operating costs.

- Explosion-Proof and Hazardous Area Applications

- Advanced intrinsically safe positioners are being designed for industries such as oil & gas, chemical processing, and pharmaceuticals.

- Compliance with ATEX, IECEx, and FM safety standards ensures safer operations.

- Enhanced Communication Protocols

- Modern digital positioners support communication protocols like HART, Fieldbus, and Profibus.

- Seamless integration with SCADA and Distributed Control Systems (DCS) improves operational efficiency.

Choosing the Right Valve Positioner for Your System

Selecting the correct valve positioner depends on several factors:

- Type of actuator (pneumatic, electric, hydraulic)

- Required control precision

- Environmental conditions (hazardous, corrosive, high-temperature)

- Compatibility with control systems (analog or digital)

- Operational cost and maintenance requirements

Conclusion

Valve positioners are indispensable for achieving accurate, efficient, and reliable valve control in pneumatic systems. With advancements in IoT, AI-based predictive maintenance, and smart automation, modern positioners offer greater control, energy savings, and operational safety. Investing in the right valve positioner can significantly enhance process efficiency and reduce maintenance costs.

For expert advice on selecting the best valve positioners for your pneumatic system, contact us today!

Why Choose HybridOX Automation LLP?

At HybridOX Automation LLP, we are a leading manufacturer, supplier, and exporter of premium-quality industrial control valves. Our extensive range of pneumatic control valves, actuators, and automation solutions ensures enhanced efficiency, safety, and cost savings for industries worldwide. With a focus on cutting-edge technology and industry-specific solutions, we provide customized flow control products that meet the evolving demands of oil & gas, chemical, food & beverage, and water treatment sectors. Contact us today to explore how our high-performance control valves can optimize your industrial automation needs.