Pneumatic control valves are essential components in various industrial processes, regulating the flow, pressure, and direction of fluids and gases. Understanding their functionality, types, and applications is crucial for optimizing system performance and ensuring operational efficiency.

What is a Pneumatic Control Valve?

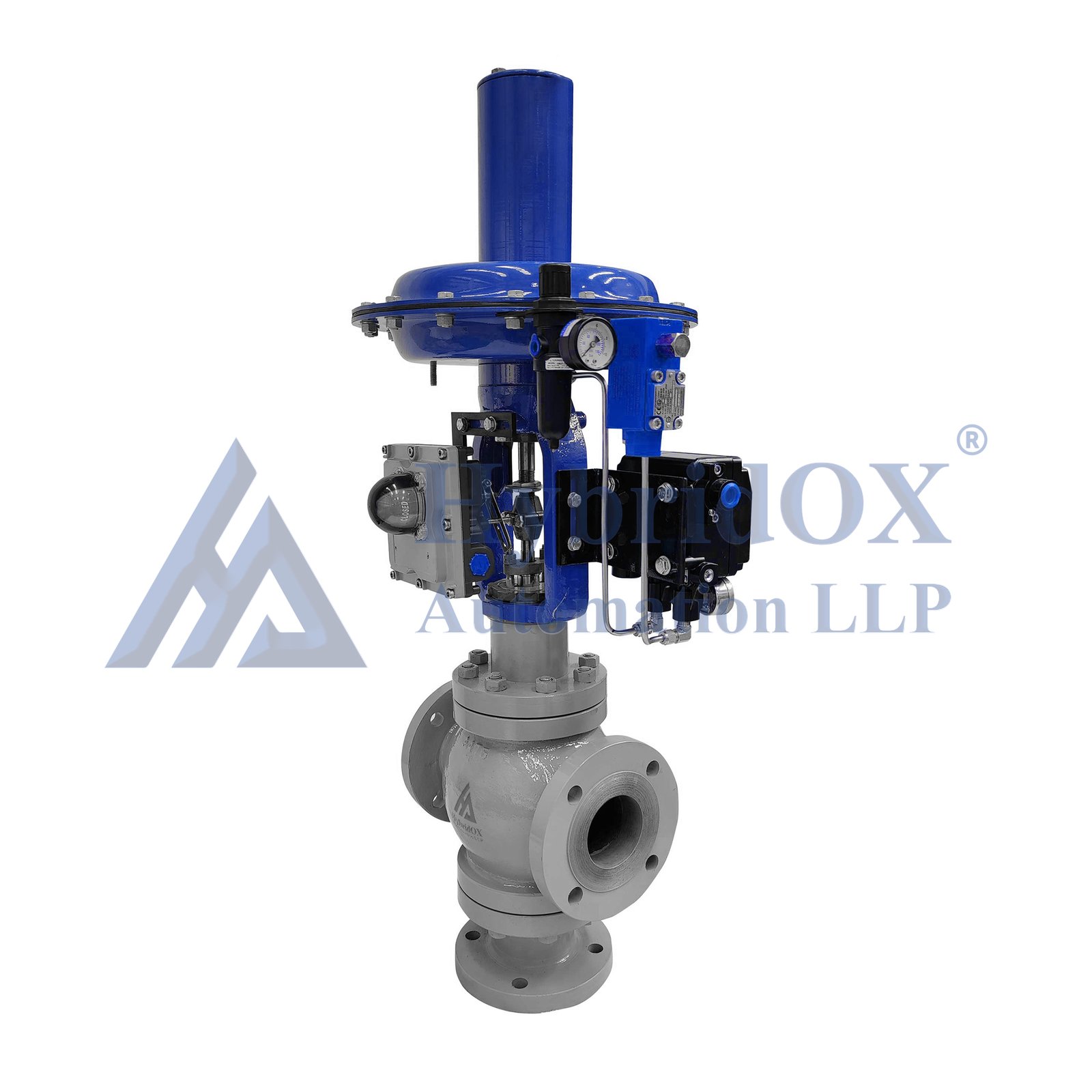

A pneumatic control valve is a device that uses compressed air as its power source to modulate the flow of fluids or gases within a system. By adjusting the size of the flow passage, these valves control variables such as flow rate, pressure, and liquid levels, thereby maintaining desired process conditions. In automatic control terminology, a control valve is often referred to as the “final control element” because it directly influences the process by controlling the flow of fluid.

Components of Pneumatic Control Valves; A typical pneumatic control valve consists of three main components:

- Valve Body: This is the main part of the valve where the flow passage is located. It houses the modulating element, such as a plug, globe, ball, or butterfly, which directly interacts with the fluid.

- Actuator: The actuator provides the necessary force to move the valve’s modulating element. In pneumatic control valves, actuators use air pressure to create linear or rotary motion, enabling the opening or closing of the valve.

- Positioner: A valve positioner ensures that the valve reaches the desired degree of opening. It receives a control signal and adjusts the actuator accordingly to achieve precise positioning, compensating for factors like friction or wear.

Types of Pneumatic Control Valves

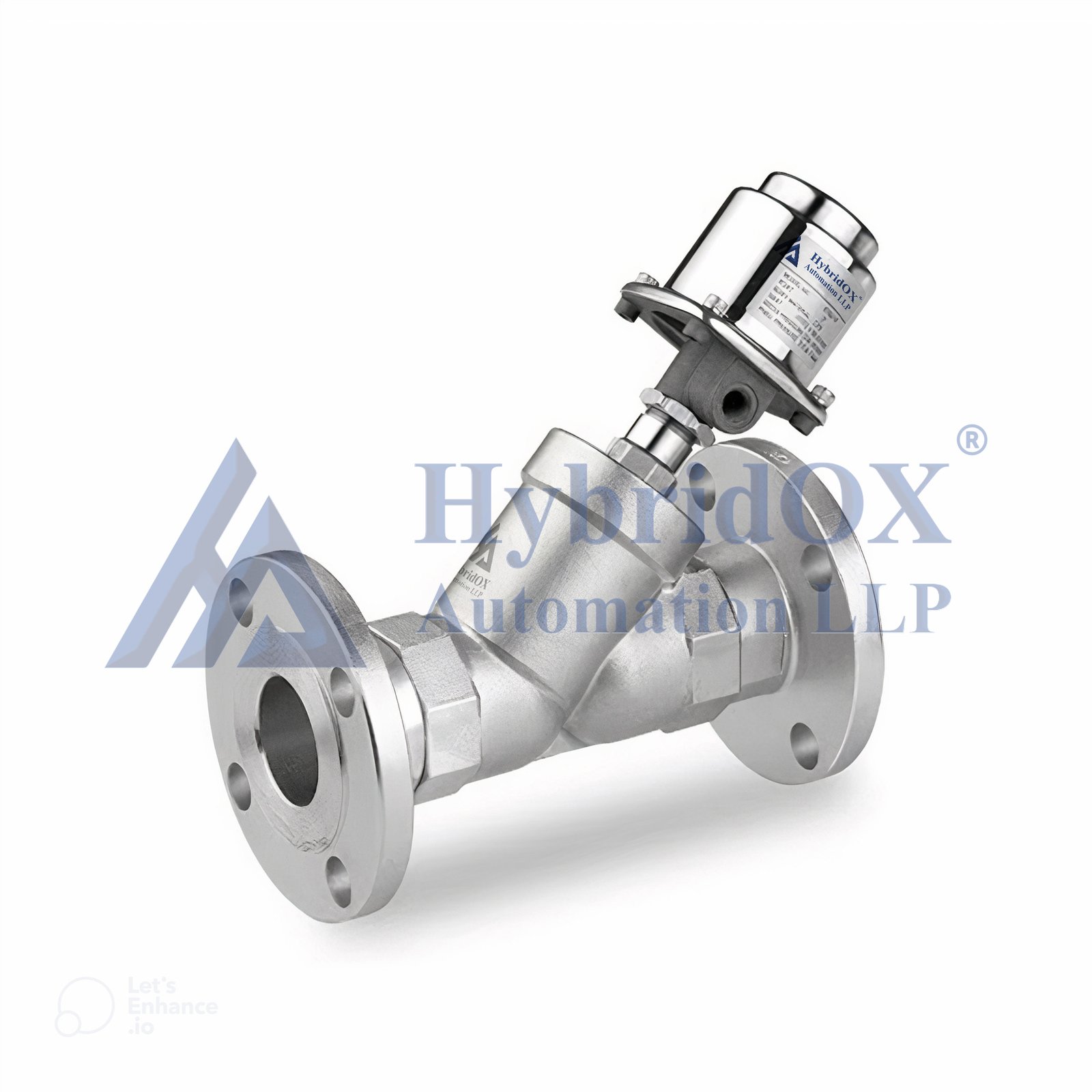

Pneumatic control valves come in various designs, each suited for specific applications:

- Globe Valves: Ideal for throttling applications, globe valves offer precise flow control and are commonly used in systems where flow regulation is essential.

- Ball Valves: These valves provide tight sealing and are suitable for applications requiring quick on-off control without pressure drop.

- Butterfly Valves: Known for their lightweight and compact design, butterfly valves are used in large-scale applications where space is limited.

- Diaphragm Valves: Utilized in systems handling corrosive or viscous fluids, diaphragm valves offer leak-proof sealing and are easy to maintain.

Operation and Control

The operation of a pneumatic control valve involves the following steps:

- Signal Reception: The valve positioner receives a control signal, typically in the form of a pneumatic pressure (3–15 psi) or an electrical signal (4–20 mA).

- Position Adjustment: Based on the control signal, the positioner adjusts the actuator to move the valve’s modulating element to the desired position.

- Flow Regulation: As the valve opens or closes, it regulates the flow rate, pressure, or level of the fluid within the system, ensuring the process variable aligns with the set point.

Applications of Pneumatic Control Valves

Pneumatic control valves are widely used across various industries due to their reliability and efficiency:

- Oil and Gas: For regulating the flow of hydrocarbons during extraction and refining processes.

- Chemical Processing: To control the addition of reactants and maintain desired reaction conditions.

- Water Treatment: In managing the flow and pressure of water during purification and distribution.

- Pharmaceuticals: To ensure precise dosing and mixing of ingredients during drug manufacturing.

Advantages of Pneumatic Control Valves

- Safety: Pneumatic systems are less prone to sparks, making them suitable for hazardous environments.

- Simplicity: They have straightforward designs, leading to easier maintenance and operation.

- Reliability: Pneumatic valves are durable and can operate effectively under various environmental conditions.

Recent Trends in Pneumatic Control Valves

The industry has seen several advancements aimed at enhancing the performance and integration of pneumatic control valves:

- Smart Positioners: Integration of digital valve controllers with microprocessors allows for real-time diagnostics and two-way communication, simplifying setup and troubleshooting.

- Energy Efficiency: Modern designs focus on reducing air consumption, thereby lowering operational costs and environmental impact.

- Material Innovations: The use of advanced materials enhances durability and compatibility with a broader range of fluids.

Conclusion

Pneumatic control valves play a pivotal role in industrial automation by providing precise control over fluid and gas flow. Understanding their components, operation, and applications is essential for selecting the right valve for specific process requirements. Staying abreast of the latest trends and technological advancements ensures that industries can leverage these valves for optimal performance and efficiency.

Why Choose HybridOX Automation LLP?

At HybridOX Automation LLP, we are a leading manufacturer, supplier, and exporter of premium-quality industrial control valves. Our extensive range of pneumatic control valves, actuators, and automation solutions ensures enhanced efficiency, safety, and cost savings for industries worldwide. With a focus on cutting-edge technology and industry-specific solutions, we provide customized flow control products that meet the evolving demands of oil & gas, chemical, food & beverage, and water treatment sectors. Contact us today to explore how our high-performance control valves can optimize your industrial automation needs.